Seamless pipes, characterized by their absence of weld-joints, offer unmatched structural integrity compared to their welded counterparts. The seamless design imparts uniform strength throughout, making them an ideal choice for applications demanding durability under extreme conditions. In this blog, we explore the diverse applications of seamless pipes and delve into the significance of material standards, including their chemical compositions.

Applications of Seamless Pipe: Seamless pipes’ exceptional strength and uniform structure make them invaluable across industries:

- Oil & Gas: Seamless pipes endure high pressure and corrosive environments, essential for transporting oil and gas.

- Refinery & Petrochemical: Seamless pipes withstand extreme temperatures and chemicals, making them vital in refining processes.

- Chemical & Fertilizer: The corrosion-resistant nature of seamless pipes suits chemical handling and fertilizer production.

- Power Generation: Seamless pipes deliver steam and fluids in power plants, handling intense pressures and temperatures.

- Automotive & Bearing: Seamless pipes serve as essential components in automobile structures and bearing systems.

- Mechanical & Structural: Their durability supports structural frameworks in construction and mechanical systems.

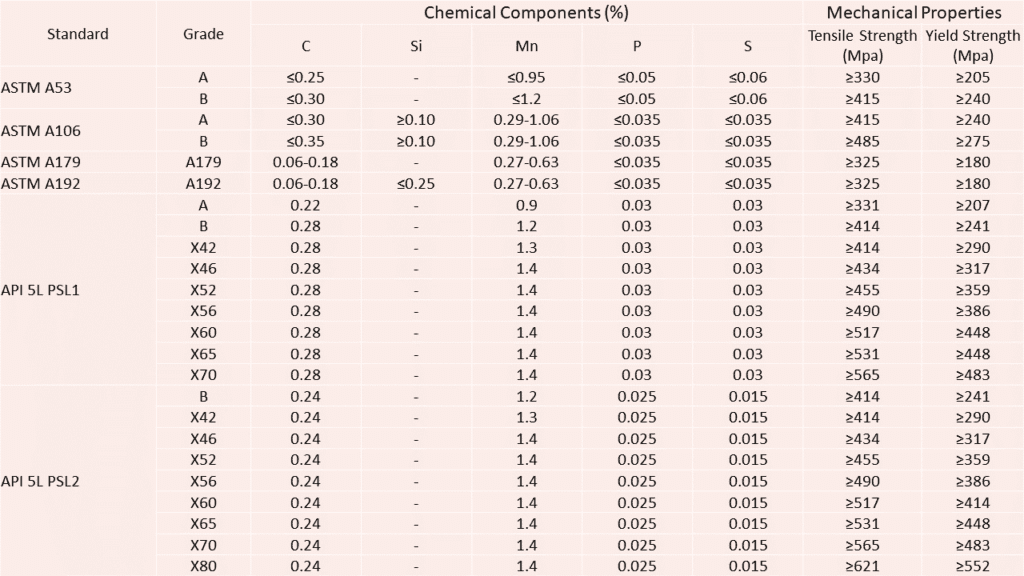

Material Standards and Chemical Composition: Seamless pipes’ material quality is regulated by standards ensuring performance and safety. Chemical composition is a key aspect:

- Standardization: Material standards dictate seamless pipe quality, outlining factors like composition, strength, and durability.

- Chemical Composition: Material standards detail chemical makeup, crucial for ensuring desired properties like corrosion resistance and strength.

Here are some Chemical compositions with Standards

Conclusion: Seamless pipes’ seamlessness translates to strength and versatility, enabling their usage in critical industries. Adhering to material standards and understanding chemical compositions is essential for ensuring reliable and effective performance. For seamless pipes that excel in a range of applications, rely on those that meet stringent quality and material standards.