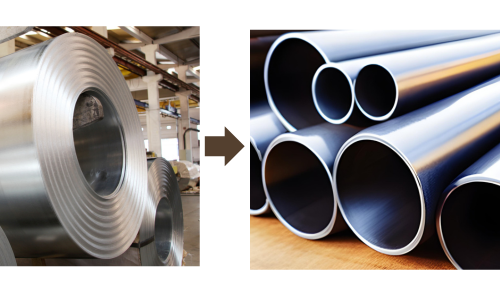

The production of Electric Resistance Welding (ERW) pipes involves a series of intricate steps that transform raw materials into robust pipes for various applications. Let’s embark on a journey through the manufacturing process, from uncoiling the steel strip to achieving impeccable straightness.

- Uncoiling: The process begins with uncoiling a roll of steel strip, which serves as the primary material for ERW pipes. Uncoiling machines smoothly unwind the steel, preparing it for the subsequent stages.

- Leveling and Flattening: The steel strip often undergoes leveling and flattening processes to ensure uniform thickness and optimal workability. This step contributes to the overall quality of the final pipes.

- Forming: The flattened strip is then passed through a set of forming rolls to shape it into a cylindrical tube. The edges are precisely aligned as the strip begins its transformation into a pipe shape.

- Electric Resistance Welding: In this crucial phase, the edges of the strip are brought together under pressure. Electric current is passed through the edges, generating heat that fuses them together without the need for additional filler material.

- Sizing and Weld Seam Removal: The welded tube is sized using various tools, ensuring its diameter and wall thickness meet specifications. Excess material and imperfections along the weld seam are removed, enhancing the pipe’s integrity.

- Straightening: To achieve impeccable straightness, the pipe passes through straightening machines. These machines correct any residual bends or deviations, ensuring the pipe meets the required standards.

Conclusion: The intricate process of manufacturing ERW pipes involves precise coordination of multiple steps, each contributing to the final product’s quality and durability. From uncoiling the steel strip to achieving perfect straightness, the journey showcases the seamless fusion of technology and craftsmanship. ERW pipes continue to play a crucial role in various industries, shaping infrastructure and facilitating the flow of essential resources. Give me meta description for the blog